Lilemong tsa morao tjena, "phetoho ea bohlale ba dijithale le ho tlola habonolo" e fetohile mokhoa oa nts'etsopele ea theknoloji ea polokelo ea thepa le thepa. Ka mor'a khōlo e phatlohang ea 'maraka oa agv / amr, koloi ea likoloi tse' nè, e nkoang e le "sehlahisoa sa phetoho", le eona e fumane tlhokomelo e phahameng ho tloha indastering ha tlhokahalo ea 'maraka oa malapeng e ntse e eketseha butle-butle. Ka sepheo sa litlhoko tsa bareki, li-hegerls li ile tsa qala mokhoa oa boleng bo holimo oa liindasteri tse bohlale tsa phallo ea litsela tse 'nè, tsa lokolla mefuta e fapaneng ea mekhoa e mecha ea ts'ebeliso ea pallet four-way shuttle,' me ea fana ka "moloko o mocha oa tharollo ea polokelo e bonolo" bakeng sa malapeng. le dikgwebo tsa kantle ho naha.

Ho theha tsamaiso ea lisebelisoa tse bohlale ka AI, ho nolofalletsa lisebelisoa tse ncha tsa thepa, le ho fana ka moloko o mocha oa litharollo tse tloaelehileng, tse feto-fetohang le tse senyehang ke phapang pakeng tsa li-hegerls le baetsi ba setso ba kopantsoeng. Ho ipapisitsoe le sena, li-hagerls li entse liteko khafetsa lefapheng la lisebelisoa tsa thepa e bohlale. Ho tloha sethaleng se bohlale sa lisebelisoa tsa software, ho ea letotong la kubao la liroboto tse bohlale tsa mobile, ho tloha ho litharollo tse bohlale tsa thepa (as/rs+amr+ai), ho ea ho tsamaiso e bohlale ea pallet four-way shuttle car, haggis Hegels o tsoela pele ho eketsa litho tse ncha ho software ea eona le hardware e kopantseng lisebelisoa tse bohlale tsa polokelo ea thepa, e le ho hlahloba sebaka se seholo sa 'maraka.

Etsa lihlahisoa tsa boleng bo holimo

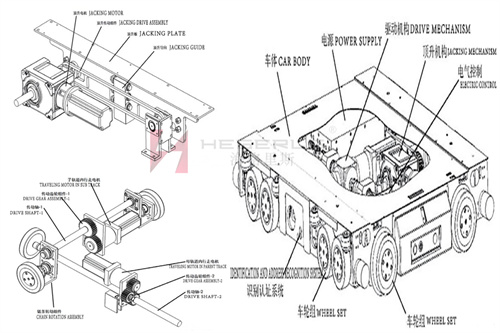

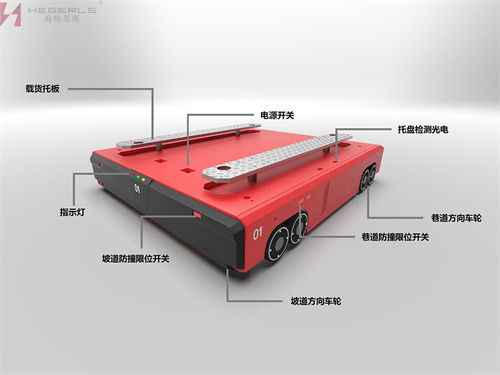

Sistimi ea shelefo ea shuttle hammoho le sistimi e tsamaeang ka litsela tse 'ne le sistimi e khethehileng ea ho phahamisa le ho boloka e otlolohileng e bitsoa "pallet four-way shuttle automatic storage system", e nang le WMS, WCS, wireless base station AP, li-server le liteishene, lishelefo tse ngata-ngata le lisebelisoa tsa tsona tse potolohileng. The pallet four-way shuttle automatic storage system e entsoe ka mochini oa koloi ea shuttle ho hlokomela ts'ebetso ea litsela tse 'ne tsa tsela e ts'oanang ea ts'ebetso ho latela litaelo tsa ts'ebetso. mokatong o le mong, ebe o kopanya lifti ho hlokomela baesekele e bohlale ea shuttle kapa ts'ebetso ea ho lekana ha lintho tse bolokiloeng, e le ho hlokomela taolo ea polokelo e matla ea likarolo tse tharo tsa sebaka sa polokelo sebakeng sohle sa polokelo. Sistimi ea eona ea tlhaiso-leseling ea taolo le taolo e ikarabella bakeng sa ho lekola maemo a ts'ebetso le kemiso ea lisebelisoa tsa kahare tsa sistimi eohle ea lishelefo, e leng ntlafatso ea kaho ea polokelo ea thepa ea shuttle le phetoho, hape ke e 'ngoe ea mekhoa e metle ea lisebelisoa tsa shuttle tse bohlale. polokelo. Ka bokhutšoanyane, pallet four-way shuttle car (eo ka mor'a moo e bitsoang "pallet four-way car") ke sesebelisoa se bohlale sa ho sebetsana le thepa ea pallet. E ka tsamaea e otlolohile le e tšekaletseng haufi le pina ea lishelefo ho phethela motsamao o tšekaletseng le phihlello ea thepa tsamaisong ea lishelefo. Ka ho fetola lera la lifti, koloi ea litsela tse 'nè e ka fetola lera, ea tšela tsela, ea fihla sebakeng leha e le sefe sa thepa sebakeng sa polokelo, 'me ea phetha mosebetsi oa litsela tse ngata. Tekanyo ea automation ea sistimi e ntlafalitsoe haholo. Ke moloko oa morao-rao oa lisebelisoa tse bohlale tsa ho sebetsana le litharollo tsa polokelo e matla ea pallet.

Ha ho bapisoa le mekhoa e tloaelehileng ea pallet automation, tsamaiso ea likoloi tsa likoloi tse 'nè e na le melemo ea ho feto-fetoha ha maemo ho phahameng, ho feto-fetoha ha sebaka se matla, ho boloka matla le ho sireletsa tikoloho, le sebaka se seholo sa ntlafatso ea bokhoni. Ha ho bapisoa le 'maraka o ntseng o hola oa agv/amr, ha ho na merero e mengata ea lapeng ea pallet ea litsela tse nne. Ka mor'a ho utloisisa lintlha tse bohloko le litlhoko tsa basebelisi morerong oa sebele, haggis Hegels e entse lipatlisiso tse lebisitsoeng le nts'etsopele ea lihlahisoa, 'me e thehile koloi ea boleng bo phahameng ba boemo bo phahameng ba indasteri e nang le monahano oa "lihlahisoa tsa indasteri". Lintlha tsa haggis Hegels pallet four-way shuttle ke tse latelang:

Likarolo tsa shuttle tsa mofuta oa tray tse 'nè:

☆ theknoloji e ikemetseng ea boto ea potoloho e kopaneng

☆ theknoloji e ikhethang ea puisano

☆ ho khanna ka litsela tse 'nè, ts'ebetso ea litsela

☆ moralo o ikhethileng, ts'ebetso ea ho fetola lera

☆ ts'ebetso e kopanetsoeng ea likoloi tse ngata mokatong o le mong

☆ thusa ho etsa kemiso e bohlale le moralo oa tsela

Thuso ea polokeho:

☆ Moralo oa sensor, pallet e ka bonoa ka nepo bakeng sa ho ts'oaroa

☆ Theknoloji ea moeli oa laser e netefatsa polokeho ea literaka tsa shuttle le thepa

☆ pina e notletsoe, 'me shuttle e matha feela pina, e sireletsehileng le e ka tšeptjoang

☆ moralo oa li-anti-slip design

☆ laser ho tloha, temoso ea pele, lebelo la maemo a mangata le taolo ea maemo

☆ Ho lemoha boemo bo matla le tiisetso ea polokeho ea sephethephethe ka nako ea nnete

Ka nako e ts'oanang, shuttle ea litsela tse 'nè e tsoang ho hegerls e boetse e na le litšobotsi tse hlano:

'Mele o mosesaane haholo: botenya ba' mele ke 125mm feela, e leng e 'ngoe ea likoloi tse tšesaane ka ho fetesisa tse sebelisoang' marakeng hajoale.

Lebelo le potlakileng haholo: nako ea ho khutlisa ha ho na moroalo ke 2.5s, nako ea ho khutlisa mojaro ke 3.5s, nako ea ho phahamisa ke 2.5s, 'me ho potlakisa ha ho na moroalo ke 2m/s2, ho hlokomela katleho ea ts'ebetso tlasa maemo a felletseng a ts'ebetso ho eketseha ka 30% .

Mamello e telele haholo: e ka sebetsa e sa khaotse bakeng sa lihora tse 8 kamora ho tjhaja hora e le 1.

Ultra e tsitsitseng: Ho ipapisitsoe le polokelo e nang le likarolo tse tharo tsa polokelo, lisebelisoa tsa polokelo le sethala sa liroboto tsa hegris hegerls, sistimi ea software ea 'mele, sistimi ea taolo ea matla, chip controller le kh'amera ea li-dimensional tse peli tsa pallet-way shuttle li tletse ka botlalo. sebedisoa hape.

Tšireletseho e kholo: likarolo tsa mantlha li khethoa ho tsoa ho barekisi ba nang le boleng bo tiileng le bo netefalitsoeng. Li-sensor tse tšeletseng tsa laser tse thibelang litšitiso li eketsoa ka pele, ka morao, ka letsohong le letšehali le ka ho le letona la 'mele oa koloi ho netefatsa ts'ebetso e bolokehileng. Ka nako e ts'oanang, pallet ea litsela tse 'nè e entsoeng ke li-hegerls e boetse e loketse libaka tse tloaelehileng tsa ho boloka mocheso le libaka tsa polokelo tse batang.

Hercules hegerls o fana ka maikutlo a hore likhoebo li khethe sekema sa li-shuttle tsa li-pallets tse nang le lintlha tse hlano:

1, Tharollo ke morero o hlophisitsoeng. Pele ho tsohle, re lokela ho etsa moralo oa mantlha ho latela litlhoko tsa khoebo ka boeona;

2、 Khetha lihlahisoa tse holileng le tse tsitsitseng tsa polokelo;

3, E itšetlehile ka moralo oa indasteri oa lihlahisoa, 'me re tlameha ho ela hloko botenya ba' mele oa koloi, hobane boima ba 'mele oa koloi ke e' ngoe ea matšoao a bohlokoa;

4, Khetha software e nang le matla a matla a thehiloeng ho algorithm ea AI, hobane software ea eona ea kamoso e bohlokoa ho feta hardware;

5, Khetha likhoebo tse nang le matla a matla le nts'etsopele e tsitsitseng bakeng sa ts'ebelisano ea projeke. Hona hape ke sepheo sa haggis Hegels ho haha mohaho o bohlale oa pallet ea litsela tse 'nè tsa shuttle.

Khokahano ea Sisteme ea Logistics e ntse e tsoela pele molemong oa maemo, modularization le ho fetoha ha maemo. Litharollo tse nang le litšenyehelo tse tlase tsa matsete a pele, ho tsamaisoa habonolo le katoloso, le phano e potlakileng li tla tsoela likhoebo tse ngata molemo. Ho fihlela sena, Hercules Hegels o ile a qala koloi e bohlale ea litsela tse 'ne, e ikemiselitseng ho theha moloko o mocha oa tharollo ea thepa e feto-fetohang ho fihlela litlhoko tsa mmaraka.

Nako ea poso: Aug-01-2022