The diversion and confluence roller conveyor e fana ka mofuta o mocha oa vertical diversion conveyor diversion roller, ho kenyelletsa: 'mele oa kheloha, letsoho, shaft le lebanta, letsoho le tsamaisana le lebanta, thepa ea shaft e bapala karolo e potolohang lipakeng tsa letsoho le shaft, 'mele oa "diversion roller" o fanoa ka groove ea ho ema ka lehlakoreng le itseng le 'mele oa ho kheloha, sebaka sa ho ema se tsamaisana haufi-ufi le lebanta,' me angle ea sebaka sa groove hangata ke 35 ° -45 °, Ho feta moo, boemo ba groove bo ka etsa hore lebanta le sebelisane le groove ea boemo ho qoba ho theoha ha lebanta nakong ea ts'ebetso ea mochine. Ho feta moo, sebaka sa groove se na le sekhutlo se itseng, 'me likarolo tsa phetiso li behiloe ka ho sebelisa inter axle le lock nut ho thusa tlhokomelo ea letsatsi le letsatsi ea rolara e khutlisetsang morao le lebanta ke basebetsi ba tlhokomelo. Ka hona, rolara e khutlisetsang morao e ka netefatsa ts'ebetso ea nako e telele ea mochini o otlolohileng oa shunting le ho ntlafatsa lebelo la ho phunya le ho hlopha, Ka nako e ts'oanang, ho loketse hore basebetsi ba etse tlhokomelo ea letsatsi le letsatsi ea moqolo o khutlisang. Sebopeho sa sebopeho sa ho kheloha le conveyor ea confluence: ho ea ka mokhoa oa ho khanna, e ka aroloa ka motlakase oa motlakase le conveyor e se nang matla. Ho ea ka sebopeho sa sebopeho, e ka aroloa ka conveyor e tšekaletseng, conveyor e fetisetsoang, conveyor ea roller, telescopic roller conveyor, joalo-joalo, e ka etsoa ka ho khetheha ho fihlela litlhoko tsa bareki ba fapaneng. Hona joale, re tla hlahisa conveyor ea "hegris hegerls" ea ho hlopha.

Li-Hagerls li arola lirolara tsa ho hlopha

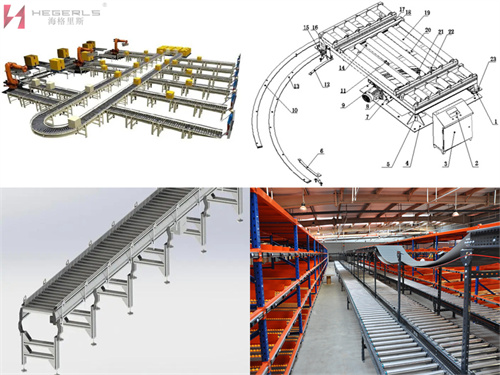

Heigris hegerls petsoha ho hlopha rolara conveyor e amohela li-conveyor tse ngata le lisebelisoa tse ling tse tsamaisang kapa mechini e khethehileng ho theha sistimi e rarahaneng ea ho tsamaisa thepa, e ka fihlelang litlhoko tse fapaneng tsa ts'ebetso; The stacking rolara e ka sebelisoa ho hlokomela stacking le ho tsamaisa thepa. Har'a bona, mochini o kopantsoeng oa rolara o loketse ho tsamaisa thepa ka tlase e bataletseng, 'me o khona ho hlokomela litšobotsi tsa lipalangoang tse fapaneng tsa collinear shunt; E le ho etsa bonnete ba hore thepa e tsamaisoa hantle, bonyane li-roller tse tharo li tlameha ho kopana le thepa e tsamaisoang ka nako leha e le efe, 'me liphutheloana tse bonolo tsa mokotla li lokela ho tsamaisoa ka li-pallets ha ho hlokahala. Hercules Hegels e arola li-roller conveyor e na le litšobotsi tsa matla a maholo a ho tsamaisa, lipalangoang tse bobebe le tlhokomelo e bonolo. E sebelisoa haholo mefuteng ea conveyor.

Sebopeho sa li-hegerls tse arolang li-roller conveyor

The petsoha arola rolara conveyor e entsoe ka foreime, li-roller, maoto, joalo-joalo, e leng e loketseng haholo bakeng sa thepa e boima ea ho tsamaisa thepa. The petsoha arola rolara conveyor e ka tsamaisa thepa ka boima bo le bong bo boholo kapa ho jara boima ba tšusumetso e kholo. E ka boela ea etsoa lithapo tsa kopano le mehala ea polokelo le thepa ea lihlahisoa tse fapaneng. Mefuta ea ho khanna e kenyelletsa lebili la ketane e le 'ngoe, sprocket e habeli, lebanta la o, lebanta la friction drive joalo-joalo. Ho ea ka sebopeho sa eona sa sebopeho, e ka boela ea aroloa ka lirolara tse tsamaisoang ka matla le conveyor e se nang matla. Ka nako e ts'oanang, e ka boela ea etsoa ka ho khetheha ho latela litlhoko tsa bareki ho finyella litlhoko tsa mefuta eohle ea bareki. The petsoha arola rolara conveyor e loketse bakeng sa lipalangoang tsa mabokose a sa tšoaneng, mekotla, pallets le likotoana tse ling tsa thepa, thepa e ngata, lintho tse nyenyane kapa lintho tse sa tloaelehang, empa e lokela ho behoa pallets kapa mabokose a thekiso bakeng sa lipalangoang.

Heigris hegerls e arola lisebelisoa tsa foreimi ea lirolara tsa ho hlopha

The petsoha rolara conveyor amohela carbon tšepe polasetiki fafatsa, 'me thepa e akaretsang ke tšepe e sa hloekang kapa aluminium; Mefuta ea eona ea ho khanna e arotsoe ka mefuta e 'meli: ho khanna likoloi tsa gear le ho khanna ka motlakase; Ho na le mefuta e mengata ea likoloi, e leng: lebili le le leng, lebili le le leng, lebili le le leng, le-o-belt, leqhubu la lebanta le bataletseng, le khanna ka lebanta, joalo-joalo; Mokhoa oa eona oa lebelo le phahameng ke taolo ea maqhubu, phetisetso e se nang mohato, jj.

Litlhaloso tsa li-hegerls tse arolang li-roller conveyor

Bakeng sa li-conveyors tse pharaletseng ka har'a mefuta e hlokoang ke bareki, li ka etsoa ho latela litlhoko tsa bareki. Mehala e tloaelehileng ka har'a sebaka sa ho phethoha ha ho phethoha hangata ke 300, 600, 900, 1200mm, joalo-joalo, kapa ho latela litlhaloso tse ling tse khethehileng tsa bareki; Bophara ba moqolo o otlolohileng hangata ke 38, 50, 60, 76, 89mm, joalo-joalo, 'me rolara e sebelisoa hangata. Hagerls e tla etsoa ho ea ka ntho ea lipalangoang, boholo, lebelo, boima, joalo-joalo.

Ho sebetsa molao-motheo oa hegerls arola arola rolara conveyor

The shunting roller conveyor e hlokomela mosebetsi oa ho phunya le ho kopanya thepa ka lirolara tsa motlakase. Karolo e 'ngoe le e' ngoe ea stacking e na le rolara ea motlakase, 'me mochine oa motlakase oa motlakase o kopantsoe le palo e itseng ea li-roller tse se nang matla ka mabanta. Ka thuso ea molaoli, thepa e ho conveyor linear fetola tataiso tlas'a boemo ba lefela khatello.

Litšobotsi tsa li-hegerls tse arolang li-roller conveyor

1. Moqapi oa modular, sebopeho se bonolo, kopano e bonolo, tlhokomelo e bonolo, ho hlokahala feela ho qhaqha li-roller tse seng kae li ka phethoa.

2. Bophahamo ba "outrigger" bo ka fetoha 'me bo na le mefuta e mengata ea kopo.

3. Ho fafatsa ka electrostatic holim'a metsi, ponahalo e ntle.

4. Li-roller conveyors li bonolo ho hokahanya le ho fetoha, 'me li ka sebelisoa li le mong, kapa mela e mengata ea li-roller le lisebelisoa tse ling tse tsamaisang kapa mechine e khethehileng e ka sebelisoa ho theha mokhoa o rarahaneng oa ho tsamaisa thepa.

5. The stacking rolara e ka sebelisoa ho hlokomela stacking le ho tsamaisa thepa.

6. E loketse feela ho tsamaisa lintho tse nang le botlaaseng bo sephara, tse sa lokelang ho tsamaisa lintho tse nang le tlase e sa lekaneng.

Bophahamo ba ts'ebeliso le ts'ebeliso ea lirolara tse arolang li-hegerls

The petsoha arola rolara conveyor e loketse bakeng sa ho tsamaisa mabokose a sa tšoaneng, mekotla, pallets le likotoana tse ling tsa thepa, tse kang thepa e ngata, lintho tse nyenyane kapa lintho tse sa tloaelehang. Eseng hoo feela, e ka tsamaisa thepa e nang le boima bo le bong bo boholo kapa e jara meroalo e meholo ea tšusumetso. Ka kakaretso e sebelisoa bakeng sa ho tsamaisa thepa ea mofuta oa lebokose le thepa e tlase e tlase. E ka boela ea kopana le karohano le ho kopanngoa ha thepa e tsamaisoang ha e kopantsoe le mochine o le mong oa ketane.

Hagerls ke khoebo ea lapeng ea thekenoloji e inehetseng ho R&D, ho etsa, ho rekisa le ho fana ka litšebeletso tsa liroboto tse bohlale, lisebelisoa tsa othomathiki tsa thepa le litharollo tsa sistimi e kopaneng ea thepa. Ho tloha ho liroboto tsa indasteri, liroboto tsa lits'ebeletso le tharollo ea liroboto ho ea ho lisebelisoa tse bohlale le matlong a polokelo a mahlakore a mararo, k'hamphani e thehile theknoloji e etellang pele lapeng le kantle ho naha Ketane e felletseng ea indasteri e kopanyang lihlahisoa tsa lisebelisoa tsa boleng bo holimo le tharollo e felletseng ea indasteri ea motho ka mong.

Lefapheng la thepa, k'hamphani e na le matla a R & D le matla a moralo, 'me e ikemiselitse ho nts'etsopele e kopanetsoeng ea polokelo ea thepa e ikemetseng, tsamaiso ea ho hlophisa, tsamaiso ea ho tsamaisa, thepa ea thepa, joalo-joalo, ho fana ka litšebeletso tsa batho ka ho fetisisa. Hajoale, k'hamphani e fihletse tšebelisano 'moho le bareki ba bangata ba maemo a holimo, mme sebaka sa eona sa khoebo se atoloha ho indasteri, khoebo ea e-commerce, lipalangoang, matla le likarolo tse ling tse ngata tsa indasteri. Khampani e etsa matsapa ohle a ho aha moralo oa khoebo oa thepa o bohlale ka lipuisano le moralo oa moralo joalo ka moetapele, nts'etsopele ea lisebelisoa tsa boleng bo holimo e le katleho, sistimi ea tlhaiso-leseling ea thepa e le moea, le kopanyo ea kakaretso ea tsamaiso ea thepa e le eona e etelletseng pele.

Ka setšoantšo sa eona se ntseng se eketseha, matla a tekheniki le mohopolo oa ts'ebeletso e tsoetseng pele, k'hamphani e kentse letsoho liindastering tse ngata, joalo ka lithaere, meriana, phano e hlakileng, khoebo ea e-commerce, mechini, liaparo, lirapeng tsa boikhathollo, thuto, sesole, lisebelisoa tsa motlakase tsa indasteri, lijo le seno, joalo-joalo Hergels e file bareki litharollo tse tšepahalang, tse tenyetsehang le tse theko e tlaase lapeng le kantle ho naha. Litšebeletso tsa eona li thusitse bareki ho boloka nako e ngata mme li ntlafalitse haholo sekhahla sa ts'ebetso le ntlafatso ea sebopeho sa indasteri. Nakong e tlang, k'hamphani e tla tsoelapele ho shebana le boqapi le phetoho e etellang pele, 'me butle-butle e fetohe "karete e ncha ea khoebo" ea indasteri ea li-automation ea naha, e thusang bareki ho hlokomela tlhahiso-leseling, bohlale le boiketsetso ba tlhahiso le thepa.

Nako ea poso: Jul-21-2022