Ho rua molemo ho nts'etsopele e potlakileng ea khoebo ea e-commerce, ho na le tlhokahalo e matla ea li-automation tsa polokelo ea thepa kahare le kantle ho naha.Haholo-holo lilemong tsa morao tjena, ka lebaka la ho phahama ha litšenyehelo tsa basebetsi, libaka tse fapa-fapaneng tse kholo tsa polokelo le litsi tsa ho hlopha lapeng le mose ho maoatle li ekelitse boiteko ba tsona ba ho haha matlo a polokelo ka boiketsetso.Boemong bona, litharollo tse thehiloeng litereing tse ka fihlelang polokelo e teteaneng, tšebeliso ea sebaka, le kemiso e feto-fetohang, haholo-holo ka likoloi tse bohlale tse tsamaeang ka litsela tse 'ne, li se li qalile ho hlaha sebakeng sa polokelo se bohlale.

Boemong ba likhoebo tsa tlhahiso, joalo ka ha likhoebo tsa 'mele li tobane le liphephetso tse kang ho fapafapana ha tlhokahalo, phethahatso ea nako ea sebele, le ho potlakisa mokhoa oa khoebo, litlhoko tsa bareki bakeng sa tharollo ea thepa li atisa ho fetoha le ho ba bohlale.Ho ipapisitsoe le mokhoa ona, Hebei Woke o hlahisitse sekepe se bohlale sa Hagrid HEGERLS se tsamaeang ka tsela e mene, se tlatsang lekhalo la litharollo tse feto-fetohang tšimong ea ho sebetsana le pallet pele.Mmarakeng oa kajeno, lishelefo tsa pallet e se e le mofuta o atileng haholo oa polokelo o sebelisoang libakeng tsa polokelo ea sejoale-joale tsa indasteri, litsi tsa thepa, litsi tsa phepelo le maemo a mang.

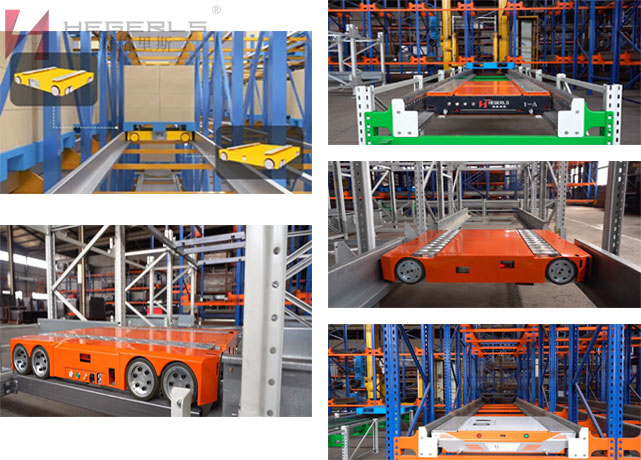

The Hagrid HEGERLS intelligent tray four-way shuttle car e kenyelletsa koloi e tsamaeang ka litsela tse 'ne, mochini o ts'oarellang, sethala sa lishelefo, sesebelisoa sa lisebelisoa (ho kenyeletsoa seteishene sa ho tjhaja, se tsamaisang thepa, taolo e hole, marang-rang le sistimi ea taolo ea motlakase), le HEGERLS ho hlophisa sistimi ea software.Ka lebaka la ho kenya letsoho ha kemiso ea likoloi tse ngata le mosebetsi oa tšebelisano-'moho le lisebelisoa tse amanang le tsona tse kang li-lifti tsamaisong ea likoloi tsa litsela tse 'nè, bokhoni ba ho hlophisa software bo tla ba le phello e kholo mosebetsing oa tsamaiso.The Hagrid HEGERLS e bohlale tray ea mofuta oa four-way shuttle e na le melemo e tšeletseng e meholo: "ultra-thin", "ultra fast", "ultra safe", "mamello e telele", le "super-high-scale-high-scale cluster schedule", e ka ntlafatsang haholo. katleho ea tlhahiso ea likhoebo.Roboto ena e ikemetseng e tsamaeang ka lishelefong e ka ntlafatsa le ho feta sekhahla sa ts'ebeliso ea sebaka sa polokelo ka 30% ha e bapisoa le litharollo tsa khale tsa thepa.Ka nako e tšoanang, HEGERLS intelligent tray four-way shuttle car e na le boholo ba 'mele ba limilimithara tse 125 feela, boima ba lik'hilograma tse 300,' me e kopane ebile e tiile.E ka boela ea sebetsana le lintho tse boima ba lithane tse 1 ho isa ho tse 1.5, e etsa hore e be bonolo haholoanyane ho sebetsa.Ha ho bapisoa le stacker ea lithane tse 10, e ka boloka ho feta 50% ea motlakase.Ha ho bapisoa le litharollo tsa li-automation tsa setso, 'mele o feto-fetohang o ka koala lishelefong, o eketsa lebelo la ts'ebetso le boima ba polokelo, o etsa hore o tšoanelehe haholo bakeng sa polokelo e batang, matla a macha le maemo a mang a ts'ebetso.

Tharollo e bohlale ea tray ea Hagrid HEGERLS ha se mokhoa o bonolo oa polokelo e teteaneng, empa ke tharollo ea polokelo e feto-fetohang le e matla ea bohlale.Monyetla oa eona oa mantlha ke taolong e ajoang ea lisebelisoa tsa discrete.Ke ka lebaka la tšobotsi ena moo basebelisi le likhoebo li ka kopanyang le ho li sebelisa ha ho hlokahala, joalo ka litene tsa moaho.Ho fapana le li-stackers tsa AS / RS, tse ka sebetsang feela litseleng tse tsitsitseng, tsamaiso ea likoloi tse 'nè e lekana ka lebaka la sehlahisoa sa eona sa hardware, se ka nkeloang sebaka ke koloi e ncha ka nako leha e le efe ha ho e-na le ho se sebetse hantle.Taba ea bobeli, ho feto-fetoha ha maemo ho bonahala ho "dynamic scalability" ea sistimi eohle, moo basebelisi le likhoebo ba ka eketsang kapa ba fokotsa palo ea likoloi tse tsamaeang ka nako efe kapa efe ho latela liphetoho tse kang nako ea nako le kholo ea khoebo, ka tsela eo ba ntlafatsa mokgoa wa ho jara.Ho phaella moo, lisebelisoa tsa discrete li amana haufi-ufi le kemiso le li-algorithms, ha taolo e ajoang e hlile e le koloing e 'ngoe le e' ngoe, e tsamaellanang le theknoloji ea sethaleng sa taolo ea AMR.Leano la kemiso la HEGERLS le ke ke la laola koloi e 'ngoe le e' ngoe ea litsela tse 'nè feela, empa hape le fana ka li-algorithms bakeng sa liphetoho tsa molumo o kenang le o tsoang ka ntle, kabo ea matla a lipalangoang, ho ntlafatsa sebaka sa polokelo, le ho ntlafatsa tsela.Mabapi le kemiso ea lisebelisoa tsa discrete kapa ntlafatso ea katleho ea sistimi ka kakaretso, bokhoni bo boholo ba mantlha bo tsoa ho software, e leng molemo oa letoto la lihlahisoa tsa mofuta oa Hagrid.Ntle le moo, Hagrid HEGERLS tray e bohlale ea litsela tse 'ne e boetse e na le melemo e latelang:

1) Taolo e bohlale

Ho ntlafatsa ka nepo ts'ebetso ea polokelo ea thepa le ts'ebeliso ea sebaka sa polokelo.Ho kopanngoa ha software ea tsamaiso ea WMS le WCS le khoebo ea ERP, SAP, MES le software e 'ngoe ea tsamaiso ea tsamaiso e ka boela ea boloka molao oa pele oa thepa le ho felisa pherekano kapa katleho e tlaase ea lintlha tsa batho ts'ebetsong.

2) Intelligent layer switching

Ka ho sebelisana le lifti, koloi ea shuttle e ka fihlela mokhoa o sebetsang oa ho sebetsa oa ho fetoha o ikemetseng le o nepahetseng;Lemoha ts'ebetso ea likarolo tse tharo tsa sebaka.Laola ka nepo ho kena le ho tsoa ha sebaka se seng le se seng sa polokelo ka har'a sebaka sa sethala sa tšepe.

3) Tsamaiso ea Matla a Sebaka

Libaka tsa khale tsa polokelo ke libaka tsa ho boloka thepa, 'me ho boloka thepa ke mosebetsi oa bona feela, e leng mofuta oa "polokelo e tsitsitseng".The pallet four-way shuttle ke sesebelisoa se tsoetseng pele sa lipalangoang se sa lumelleng feela hore thepa e bolokoe le ho bolokoa ka tlung ea polokelo ho latela tlhaiso-leseling e hlokahalang, empa hape e ka hokahana le lits'ebetso tsa tlhahiso kantle ho ntlo ea polokelo.Ho thusa ho theha litsamaiso tse tsoetseng pele tsa thepa le ho ntlafatsa boemo ba tsamaiso ea likhoebo.

4) Ho ntlafatsa tšebeliso ea sebaka sa polokelo ka katleho

Boiketlo bo fokolang ba polokelo ea matlo a khale bo fella ka tšebeliso e tlaase ea sebaka sohle le sebaka sa polokelo sa ntlo ea polokelo.The pallet four-way shuttle truck e matha ka litsela tse 'nè holim'a pina e kholo ka har'a raka,' me e ka khona ho qeta ts'ebetso ka boeona ntle le ho hokahanya ha lifereko le lisebelisoa tse ling.Ka lebaka la molumo oa pina e kholo ea sethala e le nyane ho feta bophahamo ba mochini oa ts'ebetso ea forklift, sistimi ea "shuttle automation" ea litsela tse nne e ntlafatsa ts'ebeliso ea sebaka sa polokelo ha e bapisoa le sistimi e tloaelehileng ea teraka ea shuttle. hoo e ka bang 20% ho ea ho 30%, e leng makhetlo a 2-5 a sebaka sa polokelo se tloaelehileng;

E le "moloko o mocha oa tharollo ea lisebelisoa tsa pallet flexible logistics", HEGERLS pallet e bohlale ea litsela tse 'nè, e kopantsoeng le sethaleng sa software sa HEGERLS, e ka finyella bohlale ba bongata le ho sebelisa sebaka se seholo sa polokelo ea sebaka sa polokelo.Ho phaella moo, Hagrid HEGERLS pallet e bohlale ea litsela tse 'nè e tla hlophisoa ho ea ka li-SKU tse fapaneng le libaka tsa polokelo,' me algorithm e tla buella ka ho toba libaka tse loketseng tsa polokelo ha lintho li bolokiloe ka tlung ea polokelo, ho lumella thepa hore e bolokehe ho latela melao e itseng. ho qoba tšubuhlellano nakong ea ts'ebetso e tsoang hamorao, ho ntlafatsa ts'ebetso;Ha u tloha ntlong ea polokelo, algorithm e boetse e khothaletsa sebaka se nepahetseng sa polokelo, 'me e bala lintlha tse fapaneng tse kang sebaka, tšitiso ea mesebetsi, le lethathamo la ho qetela ho fana ka sebaka se nepahetseng sa polokelo;E ka boela ea finyella pono ea lihlahisoa 'me ea sheba habonolo boemo ba sebaka leha e le sefe sa polokelo ka sebopeho sa graphical, se nang le ho ikamahanya le maemo, ho tšepahala ho phahameng, scalability e matla, le ho feto-fetoha ha maemo ho phahameng.

Nako ea poso: Apr-26-2023